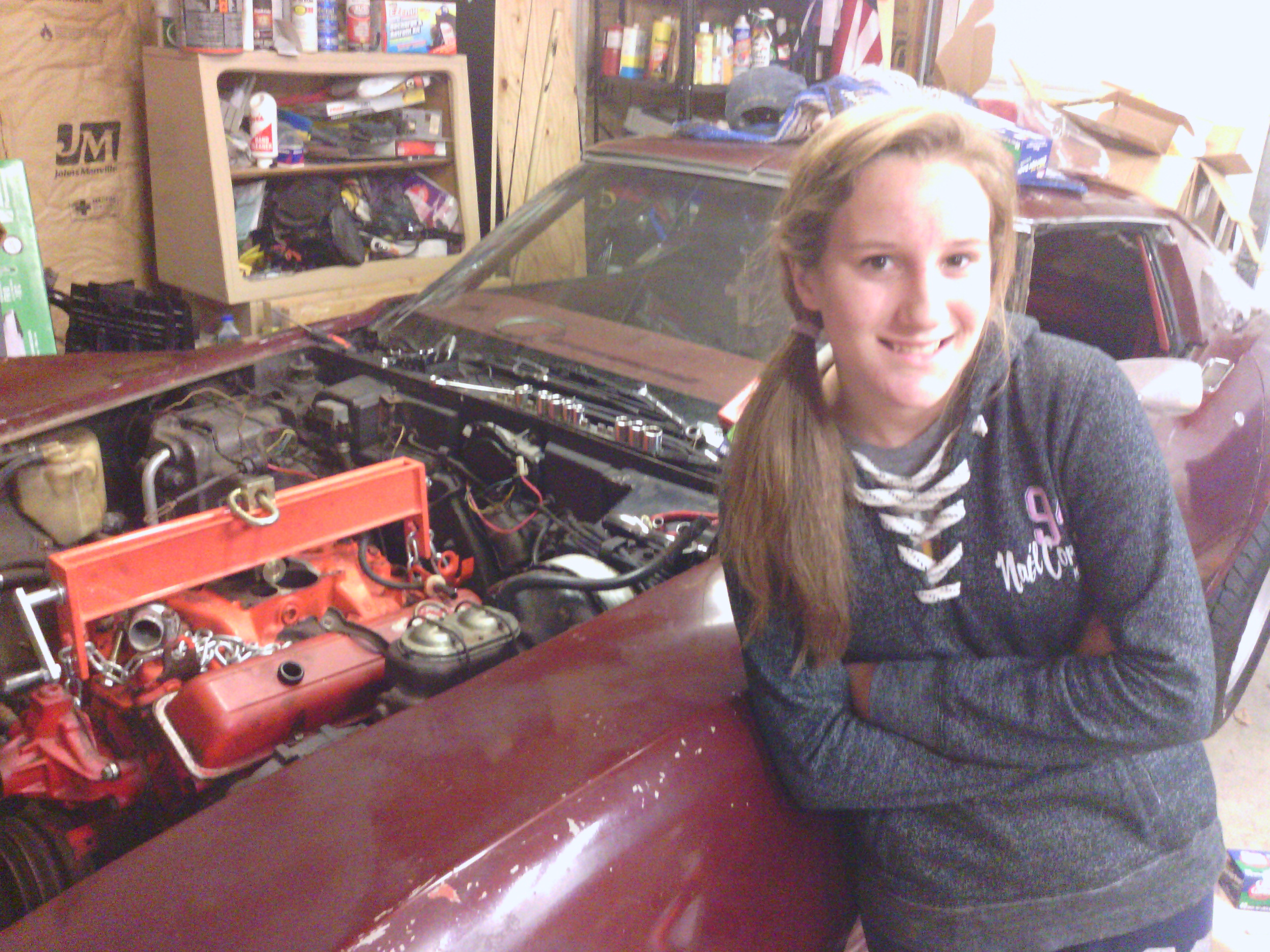

Jackie and I have been doing some small peripheral work on Cora (seat removal, master cylinder clean-up, windshield wiper removal, and carpet removal) since Thanksgiving. Also, the engine block is off at the machine shop to be bored and honed, and I expect that Jackie and will start the engine assembly sometime in mid to late January.

The stripped block ready for a trip to the machine shop.

Besides all of that, our progress has been slowed by my knee surgery that I had just before Thanksgiving (I’m more mobile now, so progress should improve in January).

Since I have a small pause before the fun begins (engine rebuilding, and body removal), I thought I might go down memory lane and explain how some of this family love of Corvettes came about. It really started back in 1976, which is coincidentally the year our Corvette, Cora, was built.

To understand where this comes from, I have always been fascinated by machines and more specifically cars and airplanes; this had a lot to do with me becoming an Electronics Engineer, a fascination that has been passed on to at least two of my kids. In 1976, this fascination was blooming right about the time that a neighbor bought a brand new “Oriole Bird Orange” 1976 Corvette. The shape fascinated me. The sound thrilled me. There was just something in the way the car was shaped that had an immediate appeal to me…a fusion of art and engineering that captivated me.

From that moment on, I would pause every time that car drove by, momentarily dazed with the synthesis of beauty and function. The coke-bottle shape, the flowing lines, the peaked front fenders, the notch-back rear window…it all just clicked for me.

Years would go by, the neighbor moved, and I would hold this love of Corvettes in my heart as a distant and un-requited love until I finally bought my own Corvette, a mahogany-red 1976 coupe.

Cora in her previous glory. Hopefully we’ll have her looking as good as this in the coming year.

This is where Cora’s story begins. Click the ‘About’ link above to learn more what has happened since.

Happy New Year everyone!